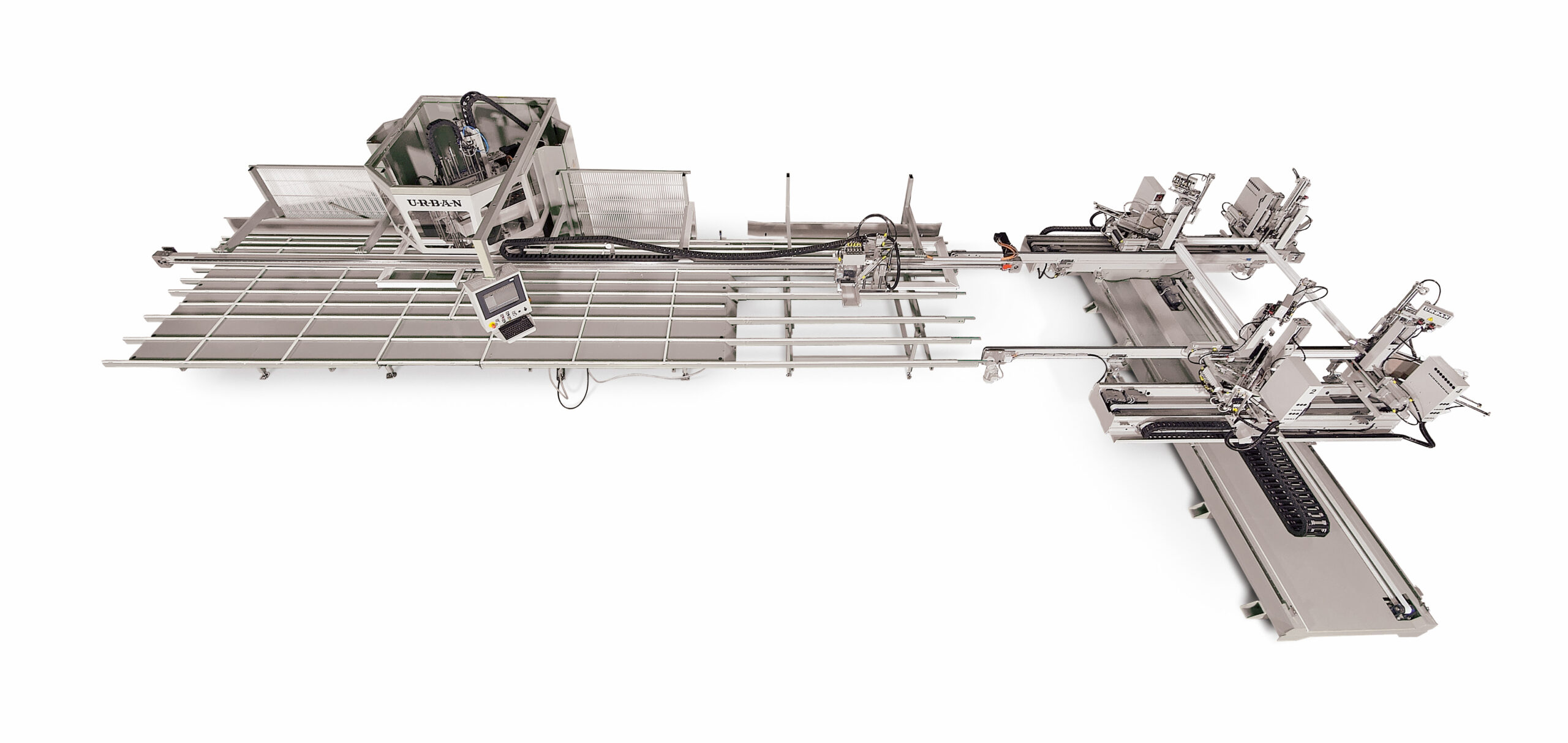

AUTOMATIC WELDING AND CLEANING LINE CC 6453

Consisted of:

– AKS 6410/4-25/35 four head welding maschine

– SV 530-B CNC cleaning maschine

– WT 530 turning station

Throught put direction: from right to left

AKS 6410 25/35 four head welding maschine:

– Four angle welding heads with parallel welding for increasing corner strength

– Weld seam limitation 2.0 and 0,2 mm at table and clamping plate

– Device for compensation of +/cutting tolerances

– Mobile clamping slide for easy insertion of the profile bars

– Integrated straight outer contour limitation 40-200mm

– Control via industrial PC with Windows basis

– Inclusive automatic discharge

– Welding measure: max. 3500mm (widthX) x 2500mm (lengthY)

– Welding measure: min. 380mm (widthX) x 320mm (lengthY)

Accessories Welding Machine

- SH Manual barcode scanner to read-in profile identification via bar code

- SHE lump sum for setting of barcode scanner

- AKS-SV Online connection to cleaning machine

- QSV Crush slit adjusting, weld seam limitation automatically adjustable,

identical at upper and lower side

- ZU ZE-6400 fixture release, central

- DFAW-6400 gasket moulder for angle heads, automatic sensoring of the inner corner

- DFAW RA-6400 surcharge for turret stop, for gasket moulder with 6 different positions,

automatic selectable via PC

- AKS-AAKD preparation for welding machines, with gasket moulder

- Color-S2, Incl. clamping cylinder with high compressive force (DM63)

and limitation knife in hardened version

- HFL- HVL 64/66 Height displacement of heater plate, for stepped welding of profiles

- Cube welding for AKS 6400 – special configuration

- FWS Remote service module via internet connection

SV 530-B CNC cleaning machine, 2 axes, with turning station WT 530:

– For rational processing of PVC window frames with interpolating axes

– Industrial PC

– Free programmable CNC control, to be programmed directly on screen, USB connection, connection

possibilities: bar code reading device, serial online connection, external keyboard;

– Simple programming of machining steps in group technique, single program selection, list or automatic

– Operator friendly diagnosis and service routine

– Frame inner stop

– Profile height : min. 20 mm, max. 200 mm

– Profile width : min. 20 mm, max. 150 mm

– Frame inside dimension: 210mmx210 mm

– Standard set of tools:

- NO 530-B – cleaning knife – top

- NU 530-B cleaning knife – bottom

- IO 530-B inside cleaning knife – top

- IU 530-B inside cleaning knife – bottom

- BO 530-B drilling unit – top

- BU 530-B drilling unit – bottom

- SF 530-B cutting disc

- PE 530-B profile identification

- DV 530-B turning station preparation

- WT 530 turning station with direction from right to left

Cleaning machine accesories

- IUS-530-B Inside cleaning unit bottom x 3

- NU-GU/2-530-B Grooving/cutting knife unit, horizontal, bottom

- NU-530-B Second grooving knife unit bottom

- NO-530-B Second grooving knive unit top

- SF-KO-530-B Skimmer blade on disc cutter unit

- MSHO-530-B Knife cutting unit, horizontal, top

- IOS-530-B Inside cleaning unit, top for inclinations > 15°

- MSVU-530-B Knife cutting unit, vertical, bottom

- BO-530-B Cutting/drilling unit, top

- BU-530-B Cutting/drilling unit, bottom

- PH-530 B profile height 200 mm

- Light barrier -B, for the recognition of left elements at the discharge of the

turning station